Conway Concrete Company Concrete Foundation Fundamentals Explained

Wiki Article

Get This Report on Concrete Driveway

Table of ContentsThe smart Trick of Conway Concrete Company Concrete Foundation That Nobody is Talking AboutTop Guidelines Of Conway Concrete Company Concrete ContractorConway Concrete Company Concrete Driveway Things To Know Before You BuyThe Facts About Conway Concrete Company Conway Arkansas Revealed

include professionally produced videos taught by exercising craftspeople, as well as supplementary downloads like tests, plans, and various other materials to assist you understand the abilities.

Concrete is strong within and lovely exterior. Concrete is a composite structure product made by integrating cement (generally Portland concrete), water, crude aggregates, and also fine aggregates. From flight terminal runways and also bridges to patios and also streets, concrete is a vital component of domestic and also industrial construction across the world. Concrete is cast in several forms as well as appropriates for a broad series of uses.

Just how many sorts of concrete remain in use? This post will assist you select the sort of concrete that is appropriate for your building job. The background of concrete goes back to 6500 BC when the Nabataea traders approximately Syria and also Jordan built the very first concrete-like structures.

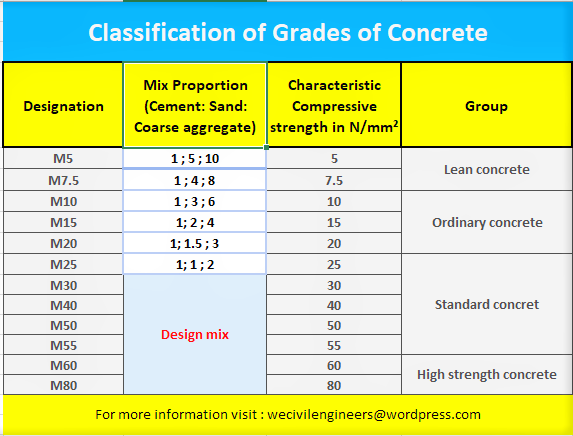

In civil engineering, the use of concrete as an architectural material is widespread and popular for the worth offered by concrete as well as its convenience of applications. A standard (normal concrete) concrete mix proportion is 1:2:4: 1 component concrete 2 components sand 4 components accumulations The above products are mixed to develop a stone-like paste that sets over time and is prepared for use in various frameworks (Conway Concrete Company concrete foundation).

Some Known Facts About Conway Concrete Company Concrete Contractor.

Often, supplementary cementitious products (SCMs) are included in concrete blends for essential advantages like decreased leaks in the structure as well as the total hardening of concrete. As an example, fly ash concrete is recognized to be a stronger concrete with enhanced toughness. Allow's get going with the most common kinds of concrete used in construction: Also known as "average concrete," ordinary concrete is made use of with a mix ratio of 1:2:4 of cement, sand, as well as accumulations.Like plain concrete, normal toughness concrete consists of comparable active ingredients but varies in stamina with 10-40 MPa. Casting concrete into a reusable mold or kind develops precast concrete that is healed in a regulated atmosphere to gain the preferred stamina.

One more essential element is the proportioning of the major ingredients so that the concrete holds other members in location. Treated precast concrete is carried to building sites for developing complete precast frameworks, such as floorings and also walls. Precast concrete structures are set up making use of cranes as well as unique hooks are supplied to lift them as well.

Prestressed concrete is industrially developed concrete that involves placing bars or ligaments at the ends of a structural system before the application of concrete. The system undergoes compression stresses throughout manufacturing to attain a higher structural load capability as well as increased toughness as well as tensile toughness. Prestressed concrete units supply faster construction as well as are generally made use of for heavily loaded structures, such as bridges and also roofings.

What Does Conway Concrete Company Concrete Patio Mean?

When already generated specialty concrete mixtures are available, they simply have to be put at building websites. As opposed to on-site concrete blending, prepared mix concrete uses high accuracy and also minimizes worksite complication. Nonetheless, admixtures like retarders are needed to maintain all set mix concrete for this page use at building sites as well much from the manufacturing facilities that generate as well as mix the concrete.As the mix establishes in 20-40 mins, it works well for projects like a fencing, mail box message, a small concrete slab, or any kind of other building and construction project that needs rapid-setting concrete. Fiber-reinforced concrete is instilled with macrofibers or microfibers to make it last longer in extreme climate condition like exceptionally cool winters.

Self-leveling concrete is appropriate for jobs that call for level, smooth surfaces. concrete company. Strengthened concrete is a composite structure material enhanced with steel bars put in the formwork throughout building.

Alternatively called "mobile concrete" as well as "flowable concrete," light-weight concrete is made from various aggregates, such as clays, pumice, shales, as well as scoria. This easy-to-pour, self-leveling concrete with low thermal conductivity is utilized for fabricating frameworks, such as flooring slabs, long-spanning bridge decks, and window panels. Light-weight concrete is also used for safeguarding steel frameworks and also is made utilizing light accumulations, consisting of: Expanded clay, broadened shale, as well as artificial shale.

The 10-Minute Rule for Conway Concrete Company Concrete Foundation

Understood as "absorptive concrete," pervious concrete's layout allows for 15% to 20% spaces of the quantity of concrete. As pervious concrete is excellent for the passage of water, it is utilized in the building and construction of driveways and sidewalks to charge groundwater and also address drainage problems.Stamped concrete obtains its name from marking or placing a sort of mold on top of the solidifying concrete to achieve an attractive concrete finish. The surface area coating mimics the appearance and also feeling of natural block, tile, behr decorative concrete finishes and also rock surface areas, to name a few. When the floor has hardened, it is normally sealed to enhance the longevity of the concrete combination.

Air-entrained concrete is concrete in which air is entrained (infused) with the addition of a foaming agent such as foam or gas. The result is concrete with billions of tiny air cells per cubic foot, with the entrained air comprising 3% to 6% of the concrete. This method gives greater resistance to concrete versus abrasion, degeneration due to cold as well as thawing, as well as scaling.

Common air-entraining representatives consist of fatty alcohols, fats, and materials. Asphalt is a dark mineral that is composed of a mix of hydrocarbons called "bitumens." Conversely called "asphalt" or "blacktop," asphalt concrete is the concrete of choice for sidewalk job and also tasks, such as flight a knockout post terminal paths, highways, car park, roadways, and pathways.

Report this wiki page